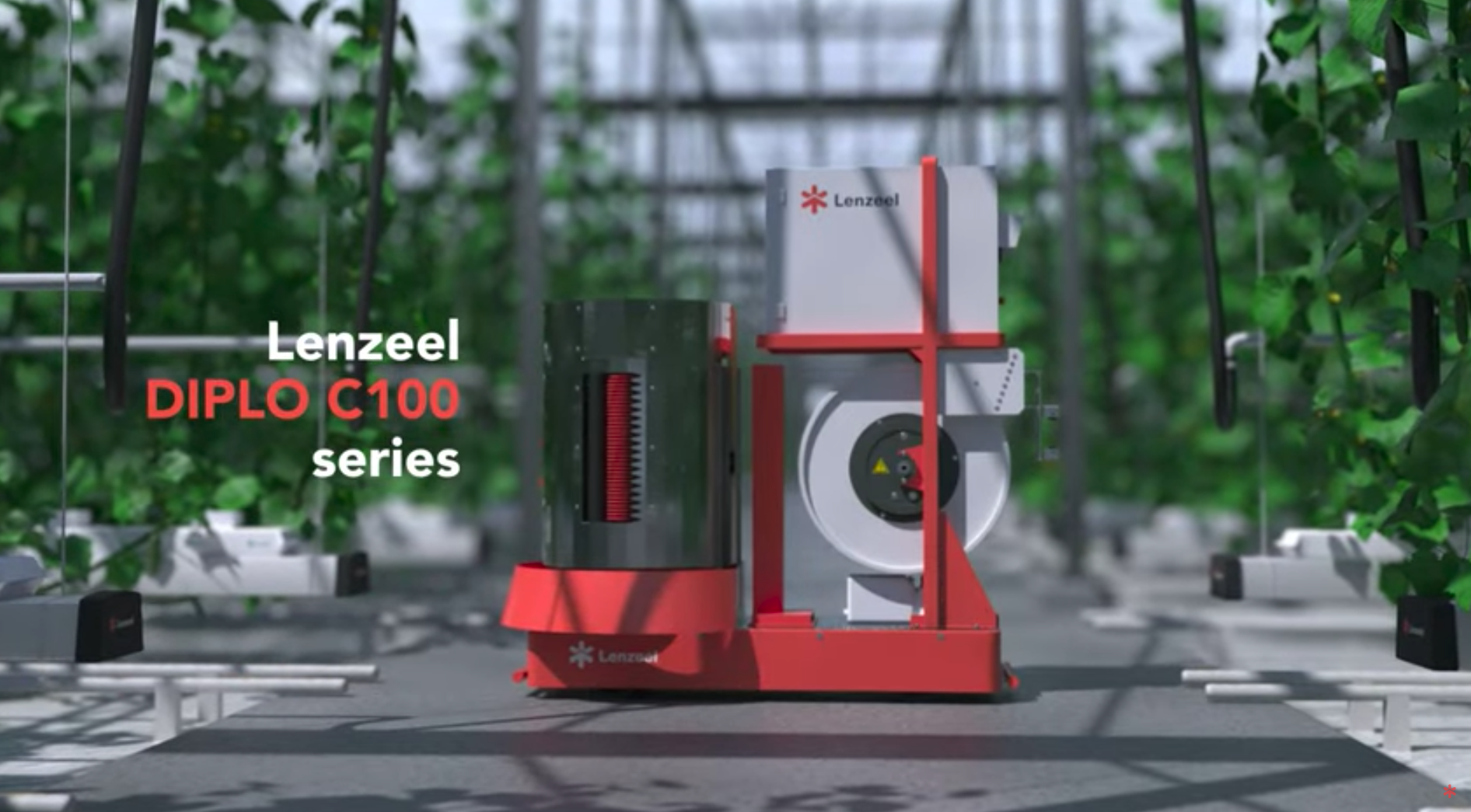

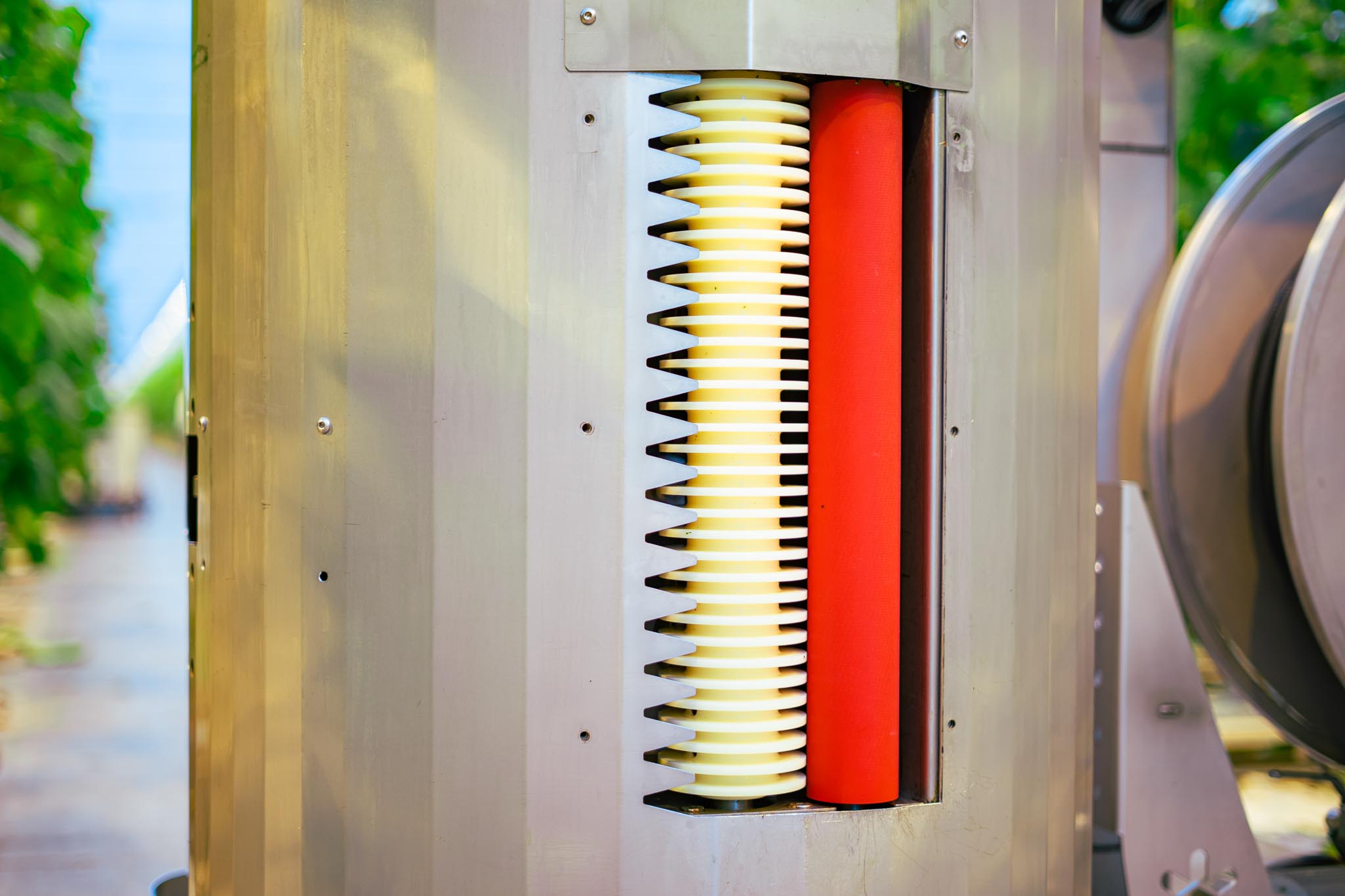

The DIPLO plucks leaves from the underside of cucumber plants in high-wire cultivation. It removes at least 80 percent of the leaves and saves more than half in picking labor. The robot has a moving platform and a picking unit with two rotating rollers made of high-quality plastic and a fan.

The platform travels along the center aisle and along the tube rails. Tags with information are located at each row, allowing the robot to know exactly where to drive. The picking unit sucks up the leaves and picks them off the stem, shreds the leaves and ejects the leaf chips. At the end of the row, the robot automatically stops, the picking unit turns and picks the other side of the row on the way back. After each row, the picking unit is disinfected with UV-C light. Unlike humans, the DIPLO never forgets to disinfect its "knife.

The DIPLO C100 uses Lenzeel patented techniques.

One hectare per 10 hours

The robot picks 1 acre per 10 hours. This can even be maximized by the planting distance.

Save at least 60%

The DIPLO immediately saves at least 60 percent of picking labor costs.

Picks at least 80%

The picking unit picks at least 80 percent of the leaves and shreds them.

Deployable soon after planting

Three weeks after cucumber plants are planted, DIPLO can be deployed.

Multigrow

'The DIPLO is picking even more than previously calculated.'